A transformer connects subsystems with different voltage levels. Examples are an 150/10 kV supply transformer and a 10/0.4 kV distribution transformer.

PARAMETERS

General

In this form the switches on both sides of the transformer can be opened or closed.

Parameter |

Description |

Name |

Name of transformer |

Tap |

Actual transformer tap position |

The transformer runs from the From-node towards the To-node. The From-node and the To-node of the transformer are determined automatically. To switch the From-node and the To-node use the <> button.

Transformer

Parameter |

Default |

Unit |

Description |

Type |

|

|

Transformer type |

Short name |

|

|

Short name transformer type for plotting in one line diagram |

Snom |

0 |

MVA |

Nominal apparent power |

Unom |

1) |

kV |

Nominal winding voltage |

Connection |

2) |

D / Y / YN / Z / ZN |

Winding connection type |

Tapside |

w1 |

|

Location of the tap changer: winding 1 or 2 |

uk |

0 |

% |

Relative short circuit voltage |

Pk |

0 |

kW |

Short circuit loss |

Pnull |

0 |

kW |

No-load loss |

Inull |

0 |

A |

No-load current (at low voltage side) |

Z0 |

0 |

Ohm |

Zero sequence impedance |

R0 |

0 |

Ohm |

Zero sequence resistance |

Side Z0 |

0 |

|

Side on which homopolar impedance is involved for YY, YZ, ZY and ZZ (0=automatic) |

Ik 2 s |

0 |

kA |

Admissible short circuit current (secondary side) for 2 seconds |

Ki |

0 |

|

Inrush current factor |

Tau |

0 |

s |

Inrush current time constant |

Clock # |

0 |

|

Transformer windings configuration |

Tap size |

0 |

kV |

Tap size of the tap changer |

Tap min |

0 |

|

Tap with smallest number of windings |

Tap nom |

0 |

|

Tap with nominal transfer ratio |

Tap max |

0 |

|

Tap with largest number of windings |

1) The default value of the nominal voltage is chosen equal to the nominal voltage of the node to which the winding is connected

2) The default connection is selected on the basis of the nominal voltage of the respective winding

Type

The type list contains all transformers from the typefile which have an Unom,w1 and Unom,w2 between the 0.8*Unom and 1.2*Unom for both the nodes.

See also: Type

Unom

If a new transformer is defined, the values for Unom,w1 and Unom,w2 are set based on nominal voltage of the nodes .

Connection

In the case of two-winding transformers in which the star point would be earthed both at the primary and secondary side (for example YNyn), the transformer enclosure would behave as a third winding in the case of an asymmetrical load or short circuit. The modelling of these transformers as two-winding transformers is not supported by Vision. In these cases, the transformer must be modelled as a three-winding transformer (YNynd).

R0 and Z0

For the calculation of short circuits with earth contact, it is checked whether: Z0> 0. If not, a warning is generated.

Clock #

The clock number is important in order to be able to calculate the phase voltages and phase currents "beyond" the transformer in case of an asymmetrical fault.

Tap min, nom and max

The indication of the tap position can be defined by the user by indicating the minimum, nominal and maximum tap position. Note that, for example, the minimum tap position can be defined as the tap position at the smallest number of windings and thus (depending on the tap side) can give the largest voltage ratio!

Copy and paste type data

The type data of transformers can be copied to a special clipboard by right-clicking in the form. A pop-up menu will appear with the Copy Type Data and Paste Type Data items. The data can be pasted into another new or existing transformer(load). This is useful, for example, for converting a transformer into a transformer load and vice versa.

Connection

Parameter |

Default |

Unit |

Description |

Neutral point |

isolated |

isolated/own/external |

Earthing of the neutral point in case of a YN/ZN-sinding |

Own Re |

0 |

Ohm |

Earthing resistance with earthed neutral point |

Own Xe |

0 |

Ohm |

Earthing reactance with earthed neutral point |

External node |

|

|

Node with neutral earth connection |

Snom' |

0 |

MVA |

Maximum apparent power; only if different from Snom |

Clock' |

0 |

|

Connection clock number; only if different from type clock number |

Phase shift |

0 |

degrees |

Phase shift of the transformer windings |

Step-up trafo |

no |

|

Indicates whether the transformer is used as a step-up transformer (IEC 60909) |

Lmax (normal) |

0 |

% |

Alternative maximum load rating in normal situation; only if different from options |

Lmax (failure) |

0 |

% |

Alternative maximum load rating in failure situation; only if different from options |

External neutral point

Allows for the use of a common earthing point for multiple transformers.

Snom'

The variable Snom' has been introduced for a uniform overload indication in the load flow. For a transformer the value is obtained as follows:

•Snom' is set from the typefile or the Snom' from the connection tab is applied.

Voltage control

Parameter |

Default |

Unit |

Description |

Own control present |

off |

|

Indicates whether the transformer is equipped with an individual voltage control |

Meas. side |

2 |

|

Measuring side of voltage control |

Node |

|

|

Node based on which the voltage is regulated |

Uset |

1) |

kV |

Setpoint of then voltage control |

Uband |

|

kV |

Deadband of the voltage control |

Rc |

0 |

Ohm |

Real part of the voltage control compounding impedance |

Xc |

0 |

Ohm |

Reactive part of the voltage control compounding impedance |

Also in backw. direction |

|

|

Also compounding when the power goes back |

Load dependent |

|

|

Choice for load dependent control |

P<< |

|

% |

Power below which is regulated at voltage U<<; above: linear between U<< and U<< |

U<< |

|

kV |

Control voltage at a power less than P<<< |

P< |

-100 |

% |

Power where on voltage U< is controlled; above: linear between U< and Uset |

U< |

|

kV |

Control voltage at a power of P< |

P> |

100 |

% |

Power where on voltage U> is controlled; below it: linear between Uset and U> |

U> |

|

kV |

Control voltage at a power of P> |

P>> |

|

% |

Power above which voltage U>> is controlled; below which: linear between U> and U>> |

U>> |

|

kV |

Control voltage at a power greater than P>> |

Master control usable |

off |

|

Transformer taps may follow a master voltage control |

Master |

|

|

Name of master voltage controlling transformer |

Status |

off |

|

Voltage control activated / deactivated or use of master-slave voltage control: |

|

|

|

Control off: no voltage control actions |

|

|

|

Own control on: individual voltage control switched on |

|

|

|

Follow master control: voltage control is a slave of the master transformer |

|

|

|

Follow master control; own control standby: voltage control is a slave of the master transformer; if the master control is switched off the individual control will be switched on |

1) The default value is chosen equal to the nominal voltage of the transformer winding, which is on the measurement side.

Master-slave regulation with parallel transformers

Master control has to do with the possibility to arrange two parallel transformers according to the "master-slave" principle, so that the tap switches of the transformers always have the same control position. The tap position of the controllers is determined by one transformer (the "Master"). With an independent regulation it can sometimes happen that this is not the case.

•With a single transformer: "Own control present" and "Own control on".

•With two parallel transformers, the choice consists of an independent regulation (both transformers then have "Own control on") or a dependent control. In the case of a dependent master slave control, the following must be specified:

•for the "Master" transformer: "Own scheme present" and "Own scheme on"

•for the "Slave" transformer: "Master control usable"; the name of the "Master" transformer; "Follow master" (the step switch follows that of the master control).

There is another option:

"Follow master scheme, own control standby". This means that the tap switch follows the master control. In case the master control is switched off, the own control is active.

When using master-slave control with parallel transformers, the master's voltage ratio is chosen or approached by the slaves with unequal types.

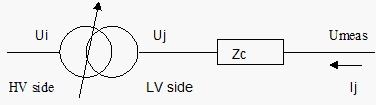

Current compensation

In load flow calculations, Vision can use the voltage control to determine a correct tap position, taking into account the secondary current (Ij) and a compounding impedance Zc. The tap position is determined in such a way that the voltage on the measured side (w1 or w2) will be within the specified voltage limits Uset ± ½ * Uband, corrected with the product of Ij and Zc. The figure below shows an example of transformer with voltage control with tap side w1 (i), measurement side w2 (j) and a fictitious measurement point on the w2 side (note the direction of Ij).

The voltage Umeas, on the basis of which the voltage control chooses a different tap, is:

Umeas = Uj + Ij * Zc

where:

Zc = Rc + jXc

The compounding in Vision takes into account the direction of the current due to the complex multiplication. Note: in practice it can occur that the absolute current value is assumed. In those cases, the model of the voltage regulation will respond differently when it is delivered back than in practice.

If Umeas> Umax or Umeas <Umin on the w2 side, a different tap mode is selected on the w1 side (until the minimum or maximum tap position is reached).

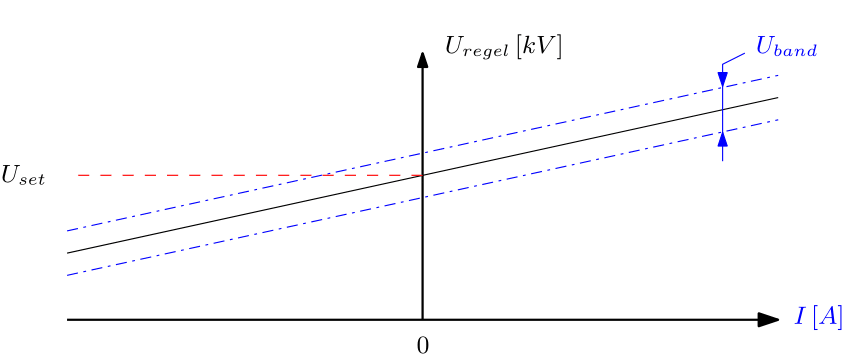

If the voltage regulation has to compensate the voltage loss over a certain connection, this can be done by indicating a compounding impedance Zc. The way in which Zc can be determined from a graph U = f (I) is indicated by the following figure.

If Rc/Zc = cos(load), the following applies:

U / I = Zc

which can be used to determine Rc and Xc:

Rc = Zc * cos(φ)load

Xc = Zc * sin(φ)load

If the values found for Rc and Xc are given in the form, the transformer voltage will be dependent on the load current.

The dead band is located around the to be controlled voltage. The transformer will not change tap if the measured voltage is between Uregel - ½*Uband and Uregel + ½*Uband.

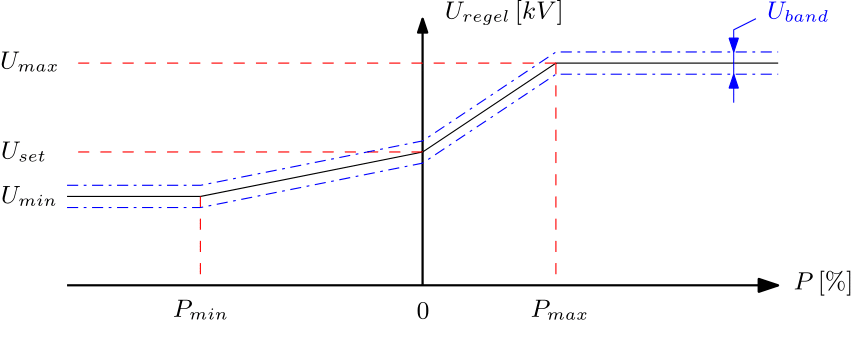

There is also a "load dependent" control.

This can be configured in a more comprehensive way than the compounding. The behaviour can be set separately for upward and downward regulation. The control limits are adjustable and follows the following figure:

Reliability

Parameter |

Default |

Unit |

Description |

Failure frequency |

0 |

per year |

Mean number of occurrences that the transformer fails (short circuit) |

Repair duration |

0 |

minutes |

Mean duration of repair or replacement |

Maintenance frequency |

0 |

per year |

Mean number of occurrences that the transformer is in maintenance |

Maintenance duration |

0 |

minutes |

Mean duration of maintenance |

maint. cut-off duration |

0 |

minutes |

Mean duration of cancellation of maintenance in case of emergency |

MODELLING

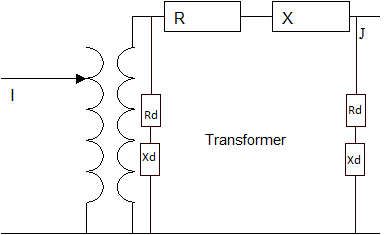

For all the calculations, the transformer is modelled in accordance to the figure shown below, in which R is determined by Pk, and X determined by uk. The tap changer is usually located on the HV-side (w1).

The voltage ratio is determined depending on the tap side in accordance with the following:

Tapside w1: ( Unom,w1 + tapstandardised * tapsize ) / Unom,w2

Tapside w2: Unom,w1 / ( Unom,w2 + tapstandardised * tapsize )

The transformer impedance is determined as follows:

Yd = Inul / (1000*Unom,ls/wortel3)

re(Yd) = Pnul / (1000*Unom,ls2)

IEC 60909 and fault analysis

In asymmetrical short-circuit calculations and fault analyses, the inverse impedance is equal to the normal impedance (Z1 = Z2).

Connection

All connection type combinations are supported. However, two sided earthed circuits are not supported because these combinations are not practical. When earthing at two sides is desired, a three windings transformer is used, where the third winding is a Delta type winding to prevent unwanted zero sequence effects.

Connection type, zero sequence and star point impedances are not important when calculating a symmetrical short circuit or a two-phase short circuit without earth contact (FFF or FF).

IEC 60909

A short-circuit calculation in accordance with IEC 60909 can be determined using a nominal tap (voltage ratio: Unom,w1 /Unom,w2) or using the voltage ratio which follows from the set tap.

The voltage control has no influence on IEC 60909 calculations. Transformers with voltage control are modelled in the same way as transformers without voltage control.

When a transformer functions as a step-up transformer, this can be stated in the form. In this case, the impedance of a step-up transformer is corrected as follows:

Rstep-up transformer = Rtransformer * cmax,LV

Xstep-up transformer = Xtransformer * cmax,LV

where:

cmax,LV is the maximum voltage factor (including in a minimum short-circuit current calculation) associated with the Unom of the node of the secondary side of the transformer

In the IEC 60909 calculation an impedance correction factor KT has been introduced for the transformer impedance ZT.

For the calculation of short circuits with earth contact, it is checked whether: Z0> 0. If not, a warning is generated.

Fault analysis

Transformers with voltage control are modelled for the sequential failure analysis in the same way as transformers without voltage control. However, a load flow calculation is performed to determine the "pre-fault" situation (sequence 0). With this load flow calculation, the step position can be determined by the voltage regulation.

Harmonics

The distributed parameter model is used for calculating harmonics. See: Harmonics: Model