An arc flash will normally be accompanied with a large amount of energy. Personell, working on an installation, must therefore be protected. The arc flash tool calculates the amount of energy that someone may be exposed to. The maximum amount of energy determines the protection grade of protective clothing.

The arc flash tool can be started by: Tools | Tools | Arc flash

An arc flash exists in a conducting medium (plasma). It originates when a current is interrupted by opening a breaker or load switch. In the case of an alternating current the arc flash will be extinguished at every zero crossing and can be reignited every half period.

The arc flash energy, which occurs during a short-circuit may be a safety risk. Therefore personnel must be adequately protected. Remedial actions involve:

•proper procedures and work instructions

•determination of the arc flash energy for each installation

•determination of personal protective clothing.

The arc flash calculation in Vision is based on the American standard IEEE 1584. This standard prescribes to first calculate the short-circuit current and hereafter calculate the arc flash energy. The arc flash energy depends on the power system, the installation and the arcing current through the plasma.

Method IEEE 1584

The arc flash energy is calculated in two stages. In the first stage the arcing current through the plasma will be calculated. With this result the arc flash energy can be calculated. Using this, the flash boundary for the available protective clothing can be established. The calculations are based on:

•three-phase short-circuit current

•nominal system voltage

•gap between the conductors

•distance between the flash and a worker

•arcing time

The model is applicable for systems with:

•Voltages in the range of 208 V–15 kV, three-phase; for higher voltages the Lee method will be used

•Frequencies of 50 or 60 Hz

•Bolted fault current in the range of 700 A – 106 kA

•Grounding of all types and ungrounded

•Equipment enclosures of commonly available sizes

•Gaps between conductors of 13 mm – 152 mm

•Faults involving three phases.

Determination of the arcing current

LV-installations (Unom < 1000 V)

![]()

Other installations (Unom > 1000 V)

![]()

where:

Ia : arcing current (kA)

Ik : three-phase short-circuit current (kA), obtained from a short-circuit calculation

Unom : nominal phase-to-phase voltage (kV)

K : factor: -0,153 for open configurations or -0,097 for closed configurations

G : gap between the conductors (mm)

Calculation of the arc flash energy

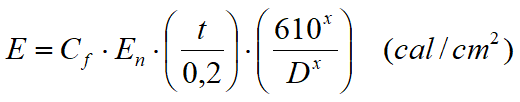

Installations with Unom < 15 kV

![]()

where:

E : arc flash energy, for specified arc duration and working distance

En : arc flash energy, normalised for arc duration and working distance

K1 : factor: -0,792 for open configurations or -0,555 for closed configurations

K2 : factor: 0 for ungrounded systems (or high resistance grounded) or -0,113 for grounded systems

Cf : correction factor for the voltage level: 1.0 for Unom > 1 kV; 1.5 for Unom < 1 kV

t : arc duration (s)

D : distance between the arc flash and a person (mm)

x : distance factor: exponent for type of installation

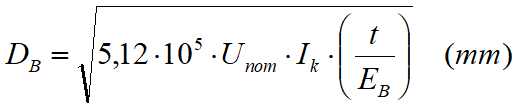

Installations with Unom > 15 kV (Lee's method)

![]()

where:

Ik : three-phase short-circuit current (kA)

Unom : nominal phase-to-phase voltage (kV)

Protection characteristics impact

The arc duration depends on the protection characteristics and the magnitude of the short-circuit current. It may happen that a small short-circuit current takes more time to be switched off. The combination of small arcing current and long arc duration may lead to a large amount of arc flash energy. Therefore, the arc flash calculation also has to be made for a lower short circuit current and the corresponding longer arc duration.

Flash boundary

The arc flash energy may lead to:

•burns

•injury due to mechanical forces.

In 1982 Lee introduced a maximum energy level for third degree burns (The other electrical hazard: electrical arc blast burns). This level is called the “Curable Burn Level” and has a value of 1,2 cal/cm2 (5 J/cm2 ).

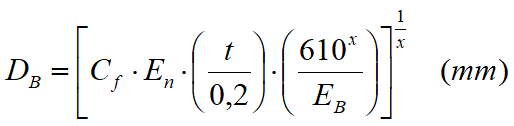

Determination of the minimum working distance

The arc flash boundary determines the required protective clothing (minimum arc rating). For installations with Unom < 15 kV the arc flash boundary is:

Installations with Unom > 15 kV (Lee's method)

where:

EB : arc flash energy on the arc flash boundary (cal/cm2)

Factors for equipment and voltage classes

Nominal voltage (kV) |

Equipment |

Typical gap between conductors G (mm) |

Distance factor x |

0,208 to 1 |

Open |

10-40 |

2,000 |

Switchgear |

32 |

1,473 |

|

Motor control and panel boards |

25 |

1,641 |

|

Cable |

13 |

2,000 |

|

>1 to 5 |

Open |

102 |

2,000 |

Switchgear |

13-102 |

0,973 |

|

Cable |

13 |

2,000 |

|

>5 to 15 |

Open |

13-153 |

2,000 |

Switchgear |

153 |

0,973 |

|

Cable |

13 |

2,000 |